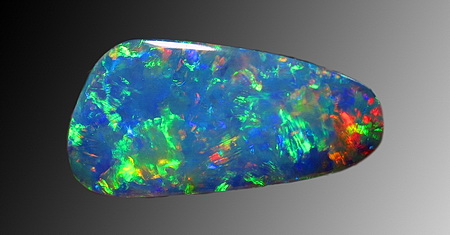

You may already know about bluish-green beryl – yes, it’s emerald. And the green-blue beryl, which is aquamarine. And of course, about their pink to the orange-pink cousin, morganite.

But what about another variation of the extremely rare mineral that is one of the gem connoisseurs’ favorite stones? If you haven’t guessed it yet, that rare crystal is red beryl.

According to the Utah Geological Survey estimates, for every 150,000 gem-quality diamonds unearthed, only a single crystal of red beryl is found.

In this post, we look at the rare and precious – red beryl.

A Precious and Rare Gemstone

Red beryl is often known as a one-source gemstone. While the crystal has been found at a few locations worldwide, including Utah, New Mexico, and Mexico, there is only a single location in the entire world where you can find crystals of red beryl that are suitable for gem cutting.

Red beryl can only be found in the Wah Wah Mountains, Utah. In comparison, the crystals extracted from the other locations are only a few millimeters in length and are too small to be used as gemstones.

But Why is Red Beryl So Rare?

The formation of the red beryl crystal requires a specific geochemical environment. Some of the essential elements required for the formation of red beryl include beryllium and manganese. Apart from the abundance of these minerals, the correct geochemical conditions are also critical, facilitating the crystallization process.

Furthermore, fractures and cavities are also another critical requirements for the appropriate growth of red beryl crystals. Hence, red beryl remains one of the rarest crystals in the world.

Red Beryl Properties

If you look at the physical properties of the rare and precious stone, it gets its rich red color from the traces of manganese. Moreover, it scores 7.5-8 on Mohs’ scale of hardness, making it a suitable material for everyday wear.

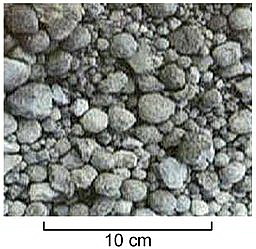

The largest known crystals of red beryl are around 5 cm long and 2 cm wide; however, most gem-quality crystals are less than 1 cm long. You can hardly find a red beryl crystal that’s heavier than one carat, and most of the red beryl crystals weigh around 0.25 carat or less.

Most of the known red beryl crystals have a rich saturated red color, allowing tiny-faceted stones to display a bright red color. Because of its rarity, red beryl can sell for over one thousand dollars per carat. Only a few red beryl specimens with a weight of more than a carat can cost several thousand dollars.

Here are a few things you should know about the rare and precious red beryl.

Gem Quality Red Beryl Comes From a Single Source

As mentioned earlier, red beryl is also known as a single source gemstone because gem-quality red beryl comes from what is known as the Ruby Violet mine in the Wah Wah Mountains, Utah. This member of the beryl family was first found in 1904 by Bixby. Following the early discovery, Lamar Hodges found another deposit of red beryl from what came to be known as the “Ruby Violet” mine in the Wah Wah Mountains of Utah.

It is still the only location in the world where you can find gem-quality red beryl. While the precious crystal can be found in other parts of the U.S. and Mexico, the crystals are too small and imperfect. As of now, the mine is closed for extraction, and there is no commercial production of gem-quality red beryl.

It Isn’t Easy to Find Good Quality, Large-Sized Red Beryl

The largest known gem-quality red beryl weighs 8 carats. Moreover, 2-carat red beryl is considered as rare as a 40-carat diamond. Moreover, the largest red beryl crystal is 5 cm long and 2 cm wide when most of the gem-quality crystals are less than 1 cm long and weigh 0.25 carats or less. Furthermore, the average carat weight of the red beryl crystals is around 0.08 carat, whereas a 0.40-carat red beryl crystal is considered large, and 1 carat is exceptionally rare.

In addition to being small, there is a significant amount of red beryl production that is not of gem quality. Of all the output of red beryl crystals from Wah Wah mountains, only 10% of it can be faceted. Moreover, less than 5% of the output was considered gem-quality material.

All of this indicates that the red beryl is one of the rarest members of the beryl family, and it is exceptionally tough to find a large-sized, gem-quality red beryl.

There is Always a Demand for Red Beryl

Despite its rarity and difficulty in finding a large-sized crystal, there is always a demand for this precious stone. One of the primary reasons for the high demand is, of course, the rarity of the gemstone. There has always been a demand for red beryl from the American market, but there is an increasing demand for the precious stone from Japan and other Asian countries over the years.

There is also a strong demand for the crystal from mineral collectors as its unique hexagonal shape, and the display of vivid red color is of exceptional interest to them.

The Rarity and Demand Always Reflect in Price

Since red beryl is a rare and precious stone that has an increasing demand in the U.S. and Asia as well, this factor heavily reflects its price. A red beryl crystal weighs more than a carat (which is exceptionally rare) and can cost several thousand dollars. However, its price also depends on several factors, including its color, size, and clarity.

Final Words

Red beryl is a rare and precious crystal which gem-quality crystals are coming from a single source. As of now, there is no commercial extraction of red beryl, which is why you can expect the price of red beryl to skyrocket in the next few years.

Tanzanite

Tanzanite