What is Cement?

If you were to say “I tripped on a cement block”, would you be wrong?

If you were to say “I tripped on a cement block”, would you be wrong?

The answer is yes because there is technically no such thing as a ‘cement’ block, but there are concrete blocks; that is to say, cement is nothing more than the ‘glue’ that binds the materials that make up the concrete block, which is usually sand and gravel. So if you were to say “I tripped on a concrete block”, you would then be correct.

According to Wikipedia, cement “sets, hardens and adheres to other materials to bind them together.” In simple terms, cement is the centerpiece of what keeps the concrete intact.

What Materials are Cement Made of?

The sand and gravel are called aggregates, and it is these materials that are bound together but remember, cement is not the material, it is the glue. So what makes up the cement?

The ingredients are mainly limestone and clay, which are extracted from quarries from around the world. Of course, the process of making cement is not that simple. The limestone is heated with clay to 2,640 °F in a kiln (an insulated chamber). This process is called calcination, which liberates molecules of carbon dioxide from the calcium carbonate (the main ingredient of limestone) to form calcium oxide, commonly referred to as quicklime.

It is here where the quicklime chemically combines with the other materials to make a hard substance, called ‘clinker‘. Gypsum is then added to make Portland cement, the most common type of cement used, which is referred to in the industry as OPC.

How does the Limestone Mixture Process Work?

The limestone rock is crushed in a machine appropriately called a crusher which reduces the limestone to a size of about six inches maximum. It is then fed into the second crusher where it is further reduced to under three inches. The mix is conveyed and then sent to a raw mill bin to be ground down even further.

In these bins are two chambers. One that dries the limestone and clay mix and the other that grinds it via hot gasses. Then, once all dry, it is moved to the grinding chamber called a ball mill. Here a cylinder contains steel balls and rotates which causes the balls to fall back into the cylinder and onto the limestone mix; hence, grinders. 4 to 20 revolutions per minute is the general rotation of the cylinder, which is dependent upon the diameter of the ball mill.

What’s left when the grinding process is done is a product of fine and coarse material. The coarse material is useless in that state and is called reject where it is returned back to the ball mill for additional grinding. A machine called a separator does this part.

Having the limestone and clay grounded down to a fine powder is still not enough to complete the cement process. The mixture must then enter a device called a cyclone which is used to separate the fine grounded material from existing gases that still exist in it.

Then, the hot gas and fine materials enter a multistage “cyclone”. This is to separate the fine ground materials from the gases.

The result – a clean, fine powdery material and is renamed kiln feed.

Next, the feed is heated via a process called sintering, which is when the chemical bonds of the material are broken down using heat, and once complete, a new substance is formed called clinker.

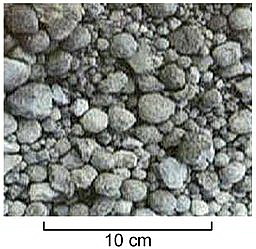

The clinker is initially very hot and contains small, dark gray nodules from 1mm to 25mm in size where it is placed into a grate cooler for cooling from approximately 2550 °F to approximately 240 °F via the use of cooling fans.

And voila! You have cement!

Final Note

Other elements are added to the clinker depending upon what the cement is going to be used for. In the case of Portland cement, gypsum is the additive.

And you thought that making cement was just adding powder and water. We hope you gained some good knowledge as to how cement is actually created. And the next time you get angry after you trip over a block that’s made up of limestone and clay, you know that it is concrete you take your anger out on and not the cement that put it together.